DTP-900

publishdate:2019-09-23 views:260

Polyvinyl chloride PvC waterproofing membrane is a polymer waterproofing membrane which is formed by extrusion of a plastic resin, an anti-UV agent, an anti-aging agent, a stabilizer and the like.

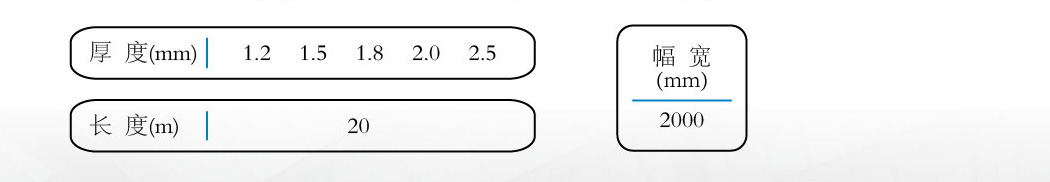

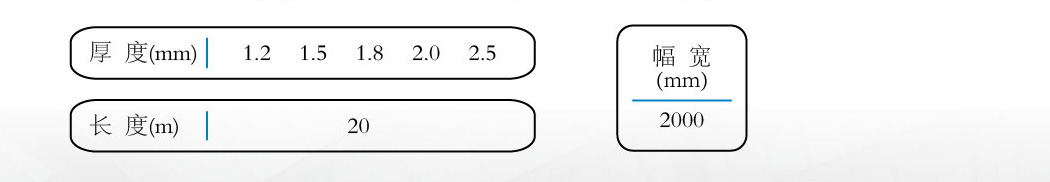

Product classification and specifications

According to the product components: fabric reinforced PVC waterproofing membrane (p); with fiber backing PVC waterproofing membrane (l); homogeneous PVC waterproofing membrane (h); glass fiber Internal reluctance type (g); fiberglass inner reinforcement with fiber backing type (gl)

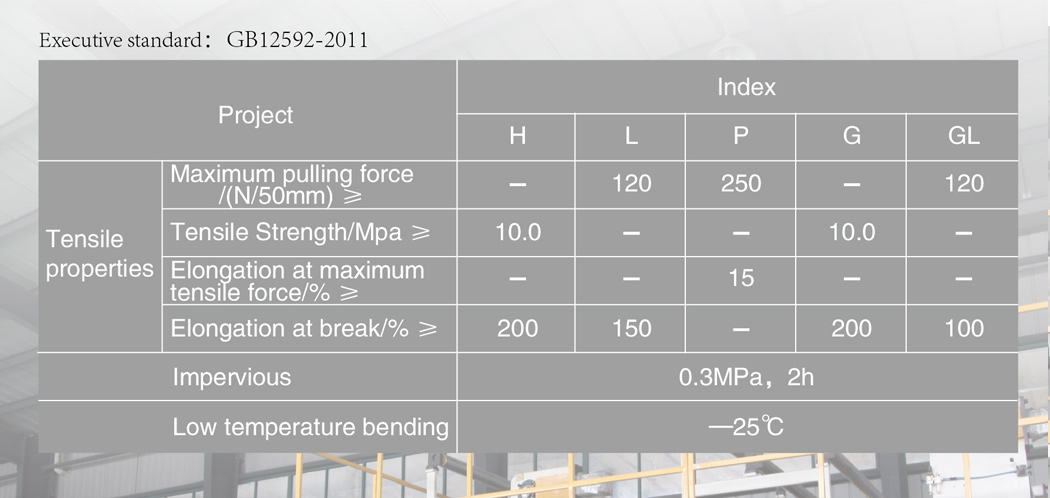

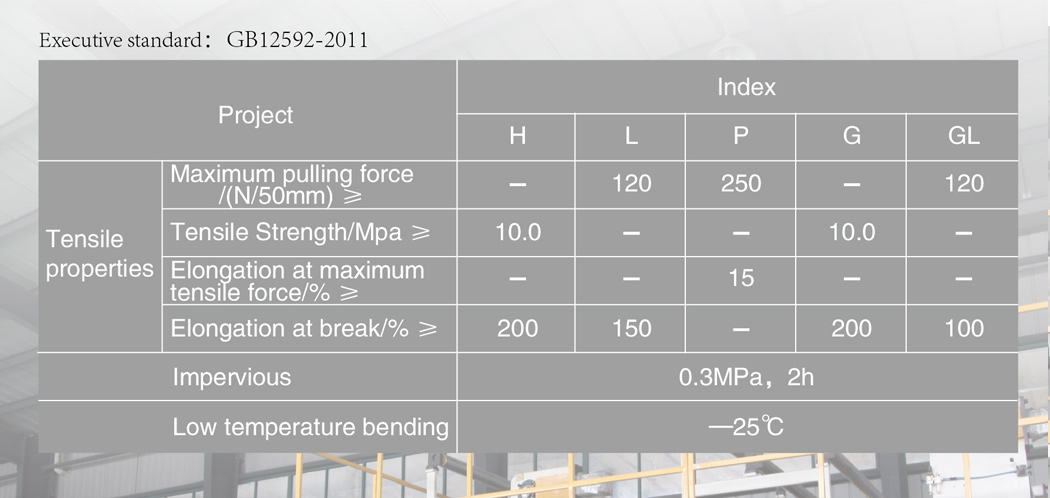

Performance

Features

▲High tensile strength, good elongation, small thermal dimensional change rate

▲ aging resistance, UV resistance, chemical resistance, root penetration

▲ has good weldability, and the seam is integrated with the substrate after hot air welding

▲With good water vapor diffusibility condensate is easy to release.

▲ low temperature flexibility, adapt to the environmental temperature difference variability.

▲The light color surface reflects ultraviolet radiation, the surface of the coil absorbs less heat and the temperature is low.

▲Long service life (25 years on the roof, more than 50 years underground), and no environmental pollution

▲Detailed processing is very convenient, easy to maintain, low cost

Scope of application

Polyvinyl chloride PvC waterproofing membrane is a polymer waterproofing membrane which is formed by extrusion of a plastic resin, an anti-UV agent, an anti-aging agent, a stabilizer and the like.

Product classification and specifications

According to the product components: fabric reinforced PVC waterproofing membrane (p); with fiber backing PVC waterproofing membrane (l); homogeneous PVC waterproofing membrane (h); glass fiber Internal reluctance type (g); fiberglass inner reinforcement with fiber backing type (gl)

Performance

Features

▲High tensile strength, good elongation, small thermal dimensional change rate

▲ aging resistance, UV resistance, chemical resistance, root penetration

▲ has good weldability, and the seam is integrated with the substrate after hot air welding

▲With good water vapor diffusibility condensate is easy to release.

▲ low temperature flexibility, adapt to the environmental temperature difference variability.

▲The light color surface reflects ultraviolet radiation, the surface of the coil absorbs less heat and the temperature is low.

▲Long service life (25 years on the roof, more than 50 years underground), and no environmental pollution

▲Detailed processing is very convenient, easy to maintain, low cost

Scope of application