DTP-800 EPDM

publishdate:2019-09-23 views:258

Epdm EPDM rubber waterproofing membrane is made of EPDM rubber with appropriate amount of butyl rubber, vulcanizing agent, accelerator, softener and reinforcing agent, etc., after mixing, pulling sheet filtration, extrusion molding, etc. An efficient waterproof membrane produced by the process.

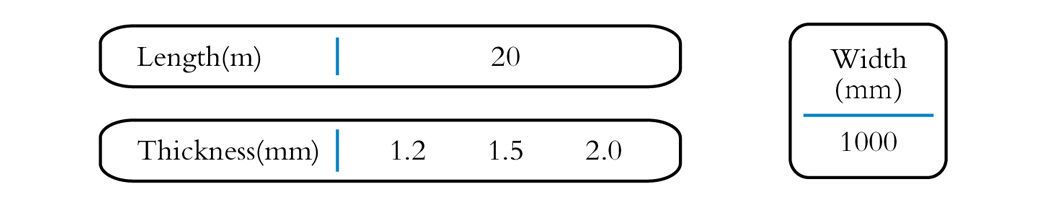

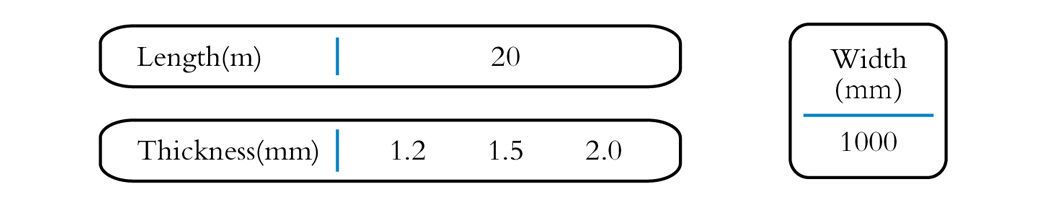

Product classification and specifications

According to the composition of the product, it is divided into: a homogenous sheet (a waterproof sheet with a polymer composite material as the main material and a uniform cross-sectional structure of each part) composite sheet (a polymer synthetic material as a main material, a protective fabric or a reinforcing layer such as a composite fabric, Waterproof sheet with uniform cross-sectional structure of each part to change its dimensional stability and mechanical properties; self-adhesive sheet (composite a self-adhesive material and a protective layer on the surface of the polymer sheet to improve or improve its adhesion to the substrate) Knotted performance, waterproof sheet with consistent cross-sectional structure of each part).

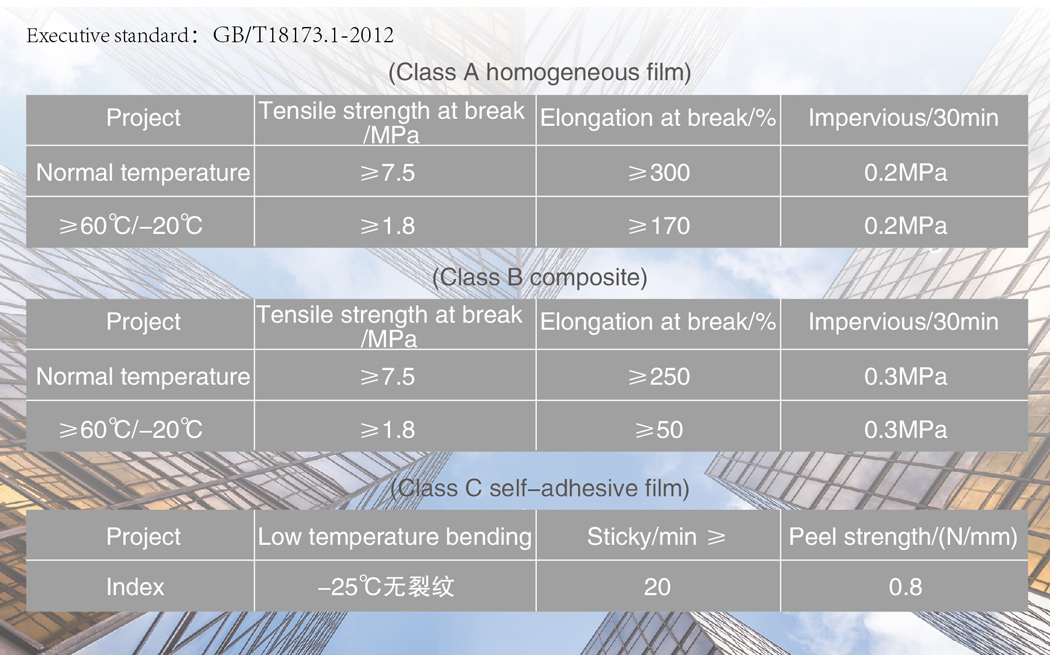

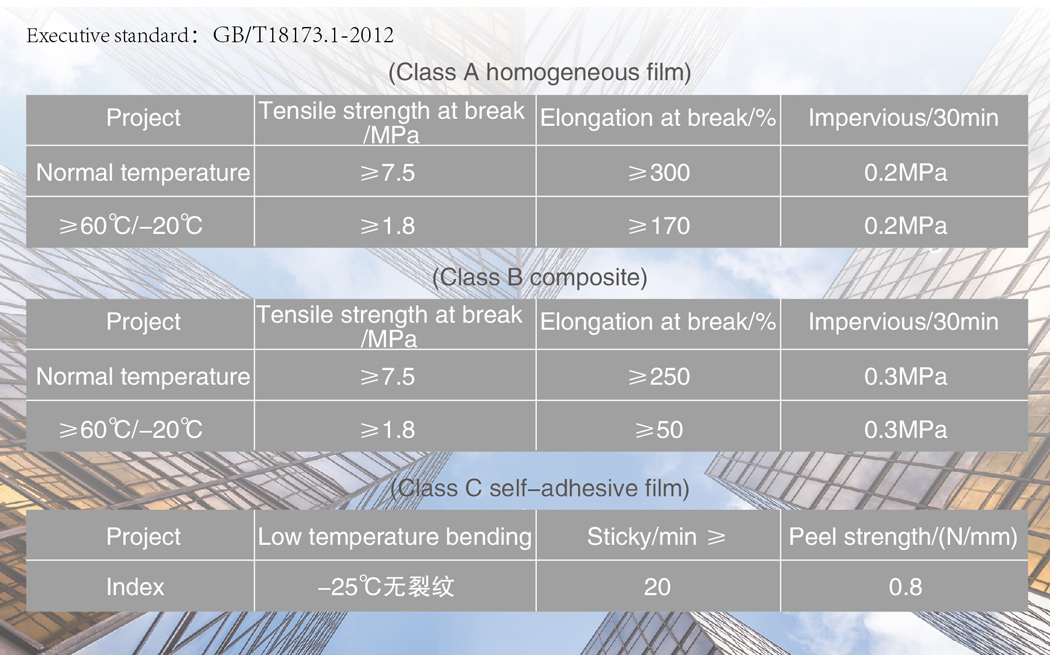

Performance

Features

▲The physical and mechanical properties are stable, durable and anti-aging. Its oil and solvent resistance is comparable to that of general-purpose neoprene.

▲Good heat resistance and cold resistance, can be used in the range of (-60-150 °C)

▲High tear strength and elongation, strong adaptability to shrinkage or cracking of buildings

▲ Light weight (0.90~0.97), uniform appearance quality, good softness and elasticity.

▲The welding property is good, the materials can be directly welded, which is beneficial to ensure the quality of the weld seam and form an integral waterproof layer after welding.

▲Good dimensional stability, small amount of heat shrinkage, small deformation, and good condition during construction

▲ environmentally friendly.No harmful substances are produced during production, construction and use, and they can be recycled without building waste.

Scope of application

Epdm EPDM rubber waterproofing membrane is made of EPDM rubber with appropriate amount of butyl rubber, vulcanizing agent, accelerator, softener and reinforcing agent, etc., after mixing, pulling sheet filtration, extrusion molding, etc. An efficient waterproof membrane produced by the process.

Product classification and specifications

According to the composition of the product, it is divided into: a homogenous sheet (a waterproof sheet with a polymer composite material as the main material and a uniform cross-sectional structure of each part) composite sheet (a polymer synthetic material as a main material, a protective fabric or a reinforcing layer such as a composite fabric, Waterproof sheet with uniform cross-sectional structure of each part to change its dimensional stability and mechanical properties; self-adhesive sheet (composite a self-adhesive material and a protective layer on the surface of the polymer sheet to improve or improve its adhesion to the substrate) Knotted performance, waterproof sheet with consistent cross-sectional structure of each part).

Performance

Features

▲The physical and mechanical properties are stable, durable and anti-aging. Its oil and solvent resistance is comparable to that of general-purpose neoprene.

▲Good heat resistance and cold resistance, can be used in the range of (-60-150 °C)

▲High tear strength and elongation, strong adaptability to shrinkage or cracking of buildings

▲ Light weight (0.90~0.97), uniform appearance quality, good softness and elasticity.

▲The welding property is good, the materials can be directly welded, which is beneficial to ensure the quality of the weld seam and form an integral waterproof layer after welding.

▲Good dimensional stability, small amount of heat shrinkage, small deformation, and good condition during construction

▲ environmentally friendly.No harmful substances are produced during production, construction and use, and they can be recycled without building waste.

Scope of application