DTP-600 HDPE

publishdate:2019-09-23 views:564

Hdpe polymer self-adhesive film waterproofing membrane is a kind of multi-layer composite waterproof material with excellent performance for the engineering part of underground engineering which requires pre-laying construction. It is mainly modified high-density polyethylene. (hdpe) is a new type of polymer waterproofing membrane made of base material and non-asphalt-based polymer self-adhesive layer. The separator is made of special performance sand or anti-aging polyethylene silicone oil film. Before the initial setting, the concrete slowly cross-links with the self-adhesive layer of the coil under the action of gravity, which causes physical adsorption and enthalpy during the solidification of the cement, so that the coil and the post-cast concrete are firmly bonded. Together, it is not easy to get out.

Product classification and specifications

The varieties are divided into hdpe polymer self-adhesive film waterproofing membrane (with sand) and hdpe polymer self-adhesive film waterproofing membrane (film) two varieties

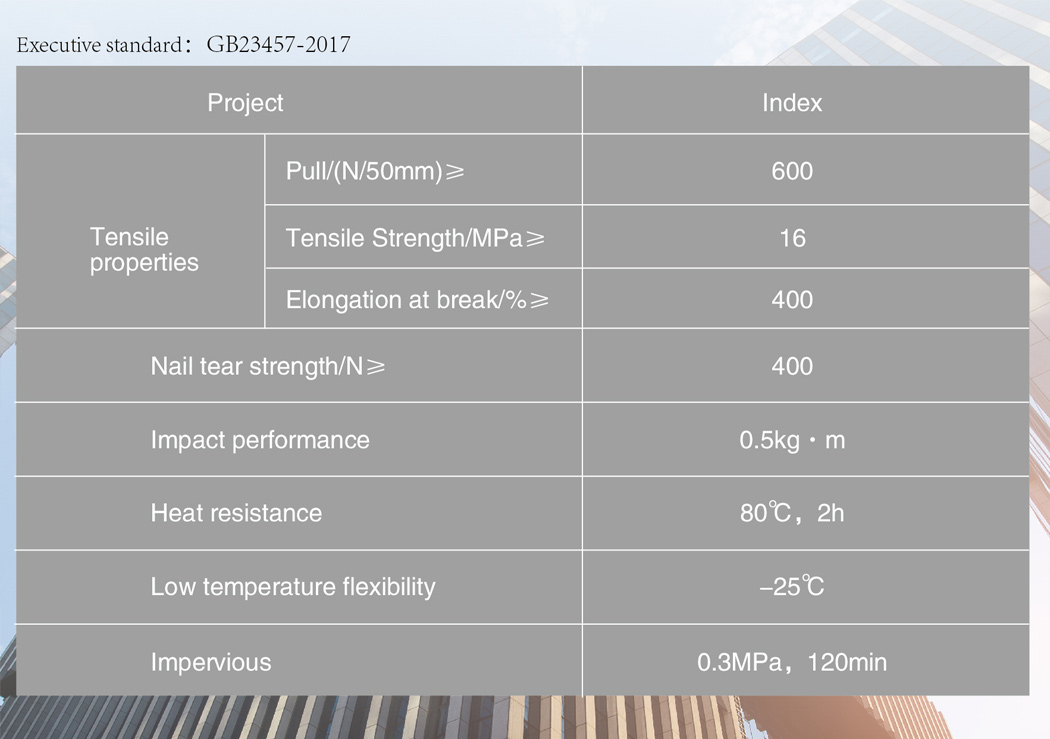

Performance

Features

▲The cement slurry and the coil bonding layer of the concrete are wet-cured and bonded by the special polymer, and the coil and the structural layer concrete form a permanent organic bond to form a gap-free structure to prevent the drowning phenomenon; even the coil Local damage, it will also limit the water to a small extent, fully improving the reliability of the waterproof layer

▲ Single-layer use meets the requirements of the first-grade waterproof fortification of underground waterproofing project, without the need for protective layer, the overall cost can be reduced by 50%.

▲Strong chemical resistance, impact resistance and puncture resistance are excellent. It can withstand the impact of construction load and steel frame directly on it. It does not require cement mortar protective layer and directly implements reinforced concrete pouring, which greatly shortens Construction period, reduce costs.

▲ Self-adhesive pressure-sensitive adhesive layer, self-healing, never cured.

▲Convenient and efficient construction: wet construction, free from weather and grassroots moisture.There is no need to level the floor without the base oil and no base baking. The rainy season construction and the construction period have their unique advantages.

▲ cold operation, no open flame, non-toxic and tasteless, no environmental pollution and fire hazard, safety and environmental protection

▲Maintenance is very convenient and fast

Scope of application

Hdpe polymer self-adhesive film waterproofing membrane is a kind of multi-layer composite waterproof material with excellent performance for the engineering part of underground engineering which requires pre-laying construction. It is mainly modified high-density polyethylene. (hdpe) is a new type of polymer waterproofing membrane made of base material and non-asphalt-based polymer self-adhesive layer. The separator is made of special performance sand or anti-aging polyethylene silicone oil film. Before the initial setting, the concrete slowly cross-links with the self-adhesive layer of the coil under the action of gravity, which causes physical adsorption and enthalpy during the solidification of the cement, so that the coil and the post-cast concrete are firmly bonded. Together, it is not easy to get out.

Product classification and specifications

The varieties are divided into hdpe polymer self-adhesive film waterproofing membrane (with sand) and hdpe polymer self-adhesive film waterproofing membrane (film) two varieties

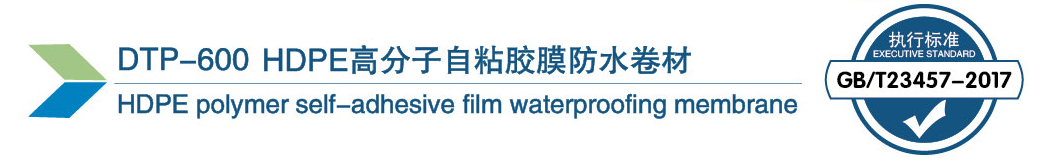

Performance

Features

▲The cement slurry and the coil bonding layer of the concrete are wet-cured and bonded by the special polymer, and the coil and the structural layer concrete form a permanent organic bond to form a gap-free structure to prevent the drowning phenomenon; even the coil Local damage, it will also limit the water to a small extent, fully improving the reliability of the waterproof layer

▲ Single-layer use meets the requirements of the first-grade waterproof fortification of underground waterproofing project, without the need for protective layer, the overall cost can be reduced by 50%.

▲Strong chemical resistance, impact resistance and puncture resistance are excellent. It can withstand the impact of construction load and steel frame directly on it. It does not require cement mortar protective layer and directly implements reinforced concrete pouring, which greatly shortens Construction period, reduce costs.

▲ Self-adhesive pressure-sensitive adhesive layer, self-healing, never cured.

▲Convenient and efficient construction: wet construction, free from weather and grassroots moisture.There is no need to level the floor without the base oil and no base baking. The rainy season construction and the construction period have their unique advantages.

▲ cold operation, no open flame, non-toxic and tasteless, no environmental pollution and fire hazard, safety and environmental protection

▲Maintenance is very convenient and fast

Scope of application