DTP-800

publishdate:2019-09-23 views:216

The polymer polyester composite waterproofing membrane is made of ethylene vinyl acetate (eva) or thermoplastic elastomer (tpo). The upper and lower surfaces of the coil are compounded with a special process non-woven fabric, and the special adhesive for zgf is used in the construction. The coil material and the cement material form a tight waterproof layer to achieve perfect waterproof effect.

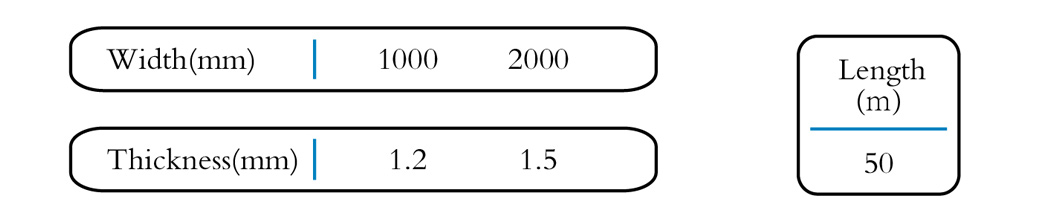

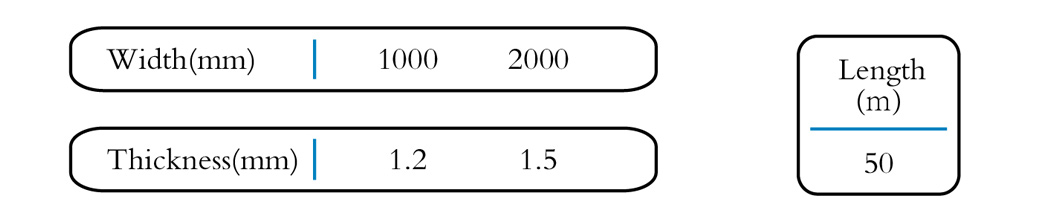

Product classification and specifications

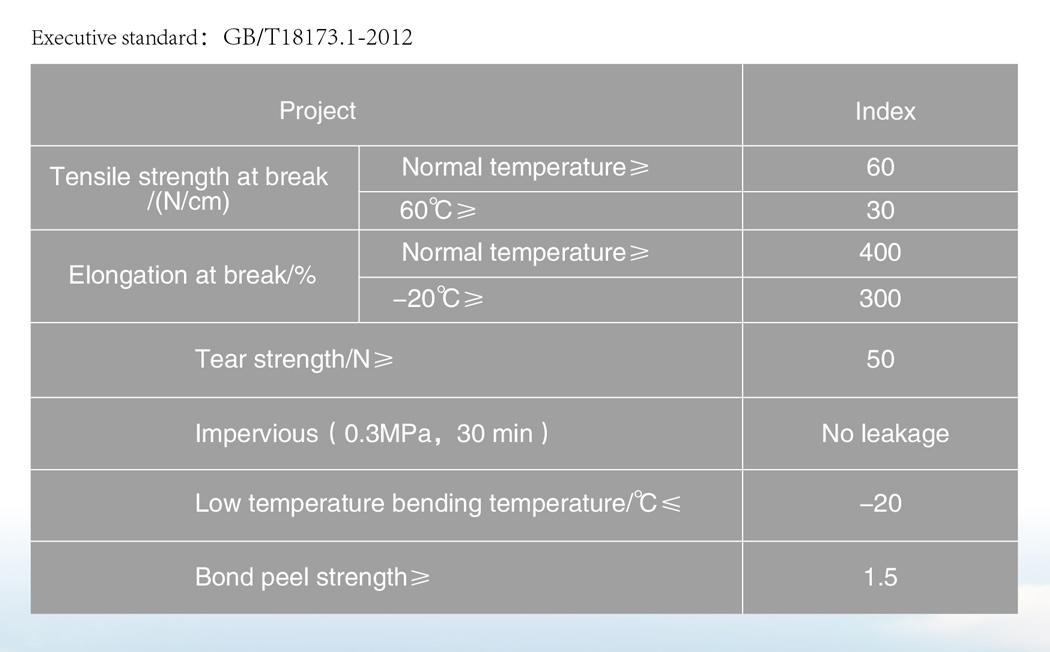

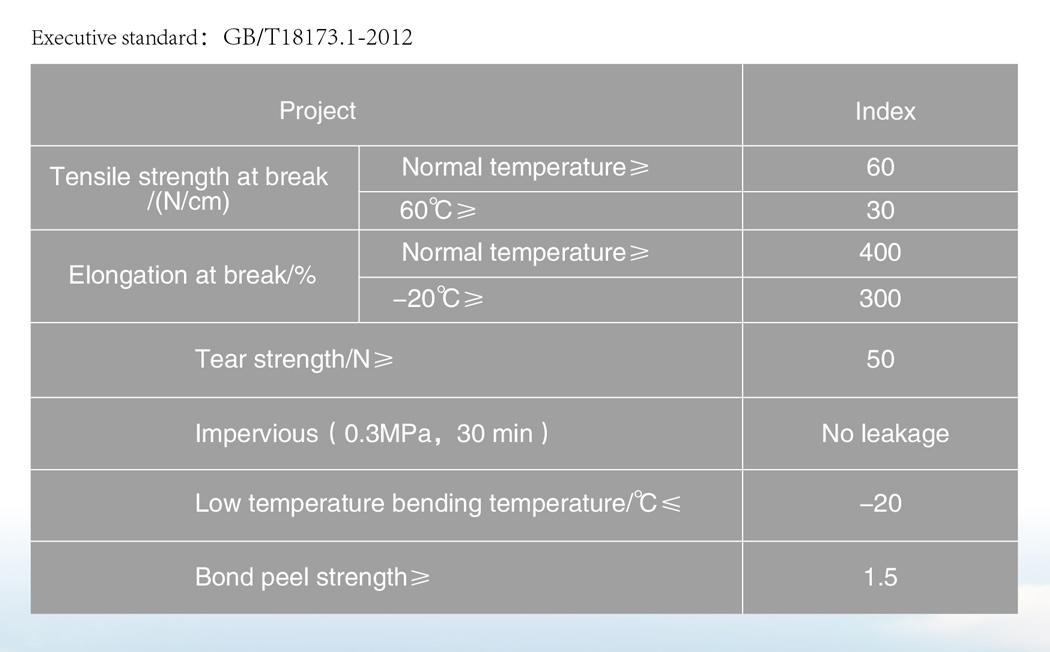

Performance

Features

▲New imported modified materials ensure softness, strength and toughness

▲ Realized the full-stick construction effect in the true sense, the full-stick effect can reach more than 95%.

▲The construction of the side wall does not need to be pre-mounted, and the paving is carried out directly.

▲The upper and lower surfaces have a three-dimensional network interpenetrating structure, which makes a good bonding effect with the adhesive, and truly meets the underground construction specification of 1.5N/mm.

▲The core layer and the composite layer can be well integrated with each other, significantly increasing the composite strength.

▲ There is no special requirement for the water content of the base surface, and no water can be used for construction.

▲ very soft, flexible and docile, easy to construct

▲ can reduce the amount of overlap in the large plane, saving material and labor costs

▲With the special adhesive, the reliability of the construction is guaranteed.

Scope of application

The polymer polyester composite waterproofing membrane is made of ethylene vinyl acetate (eva) or thermoplastic elastomer (tpo). The upper and lower surfaces of the coil are compounded with a special process non-woven fabric, and the special adhesive for zgf is used in the construction. The coil material and the cement material form a tight waterproof layer to achieve perfect waterproof effect.

Product classification and specifications

Performance

Features

▲New imported modified materials ensure softness, strength and toughness

▲ Realized the full-stick construction effect in the true sense, the full-stick effect can reach more than 95%.

▲The construction of the side wall does not need to be pre-mounted, and the paving is carried out directly.

▲The upper and lower surfaces have a three-dimensional network interpenetrating structure, which makes a good bonding effect with the adhesive, and truly meets the underground construction specification of 1.5N/mm.

▲The core layer and the composite layer can be well integrated with each other, significantly increasing the composite strength.

▲ There is no special requirement for the water content of the base surface, and no water can be used for construction.

▲ very soft, flexible and docile, easy to construct

▲ can reduce the amount of overlap in the large plane, saving material and labor costs

▲With the special adhesive, the reliability of the construction is guaranteed.

Scope of application