DTP-500

publishdate:2019-09-23 views:208

The polymer film-based wet-laid/self-adhesive waterproofing membrane is a polymer film-based double-sided self-adhesive waterproofing roll which is made of a ruthenium molecular film base as a carcass material, and then coated with a self-adhesive rubber asphalt compound on both sides. Material, mainly used for wet-laid construction or bonding with paint to form a composite waterproof system, which can achieve molecular level bonding with mortar or concrete base

Product classification and specifications

According to the function of the product, it is divided into: protective type (with modified polymer film as the base, double-coated polymer modified self-adhesive asphalt adhesive)

Waterproof protective membrane made of fiber cloth insulation with impact resistance); composite type (combined with non-cured coating)

Specialized waterproof membrane); high-strength type (with excellent bismuth molecular film base and colloid, tensile and impermeability are far greater

For conventional wet-laid coils); root-blocking type (with modified polyethylene as the base, double-coated polymer modified asphalt adhesive, when

A root-blocking waterproofing membrane made of a backing agent and a covering material is added to the colloid.

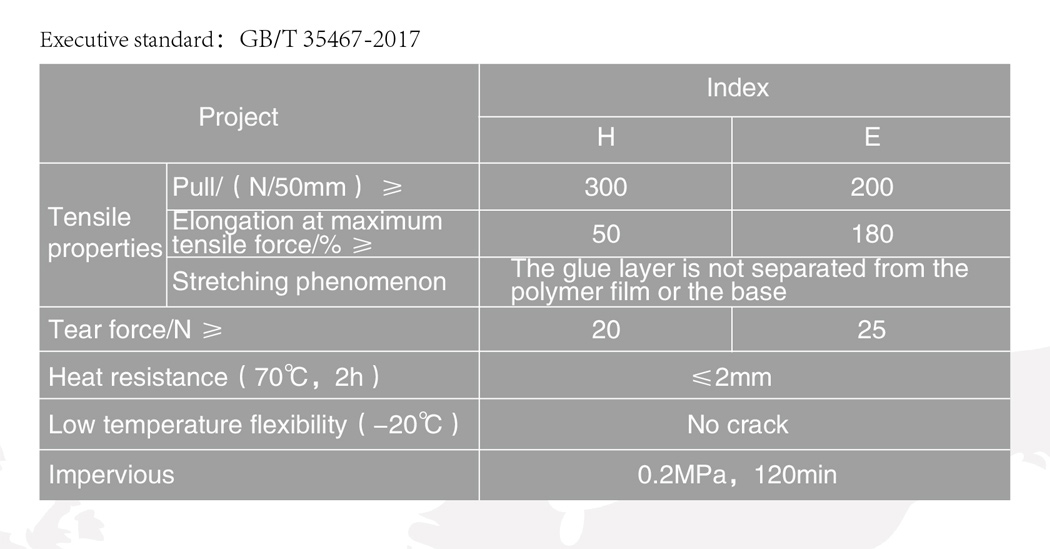

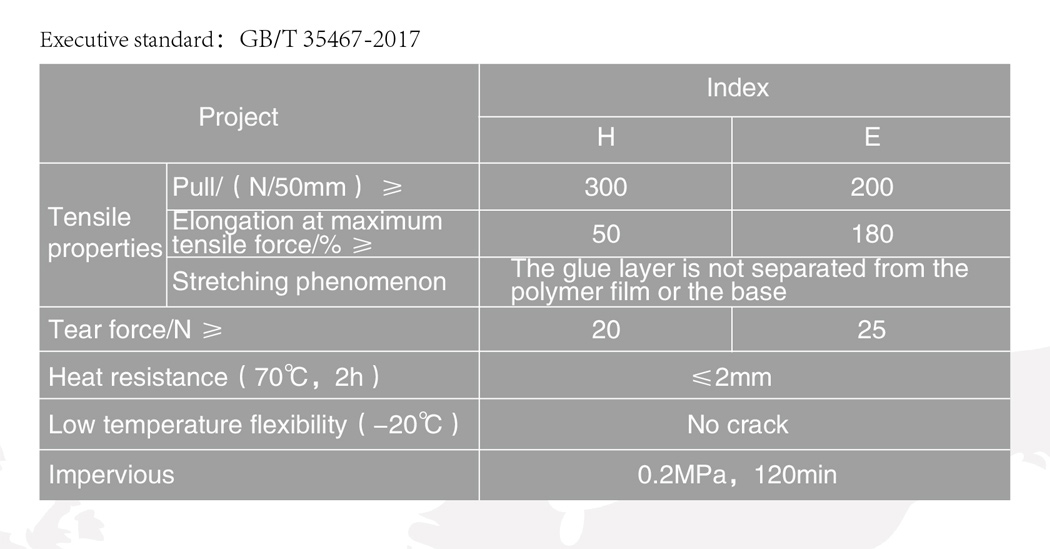

Performance

Features

▲ pressure-sensitive adhesive layer, physical + chemical cross-linking, to achieve full viscosity.

▲ product upgrade, cost reduction + performance improvement, cost-effective.

▲ polymer tire, soft texture + stable size, better performance.

▲The bottom layer is used, the wet paving construction + top and bottom is full and sticky, and it is widely used.

Scope of application

The polymer film-based wet-laid/self-adhesive waterproofing membrane is a polymer film-based double-sided self-adhesive waterproofing roll which is made of a ruthenium molecular film base as a carcass material, and then coated with a self-adhesive rubber asphalt compound on both sides. Material, mainly used for wet-laid construction or bonding with paint to form a composite waterproof system, which can achieve molecular level bonding with mortar or concrete base

Product classification and specifications

According to the function of the product, it is divided into: protective type (with modified polymer film as the base, double-coated polymer modified self-adhesive asphalt adhesive)

Waterproof protective membrane made of fiber cloth insulation with impact resistance); composite type (combined with non-cured coating)

Specialized waterproof membrane); high-strength type (with excellent bismuth molecular film base and colloid, tensile and impermeability are far greater

For conventional wet-laid coils); root-blocking type (with modified polyethylene as the base, double-coated polymer modified asphalt adhesive, when

A root-blocking waterproofing membrane made of a backing agent and a covering material is added to the colloid.

Performance

Features

▲ pressure-sensitive adhesive layer, physical + chemical cross-linking, to achieve full viscosity.

▲ product upgrade, cost reduction + performance improvement, cost-effective.

▲ polymer tire, soft texture + stable size, better performance.

▲The bottom layer is used, the wet paving construction + top and bottom is full and sticky, and it is widely used.

Scope of application