Roof engineering process standardization practice node diagram, collected first!

publishdate:2021-06-15 views:69

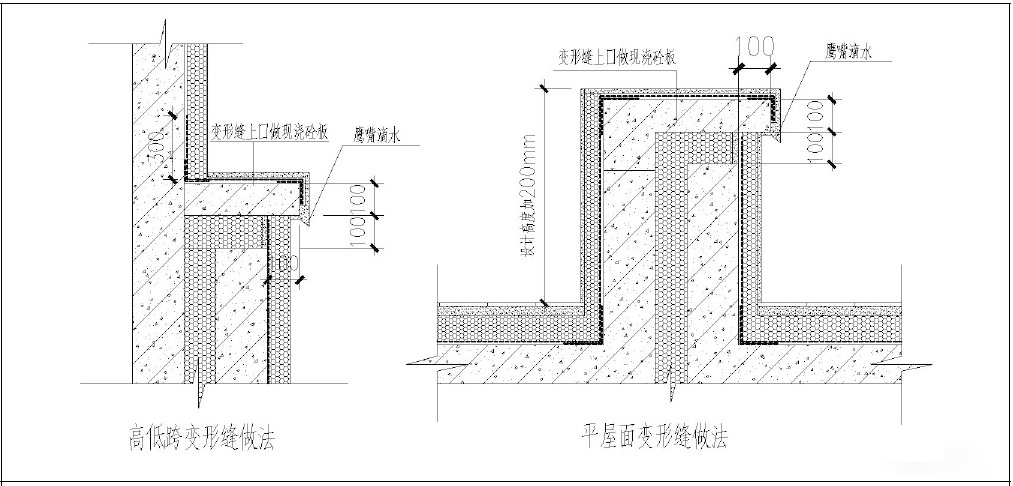

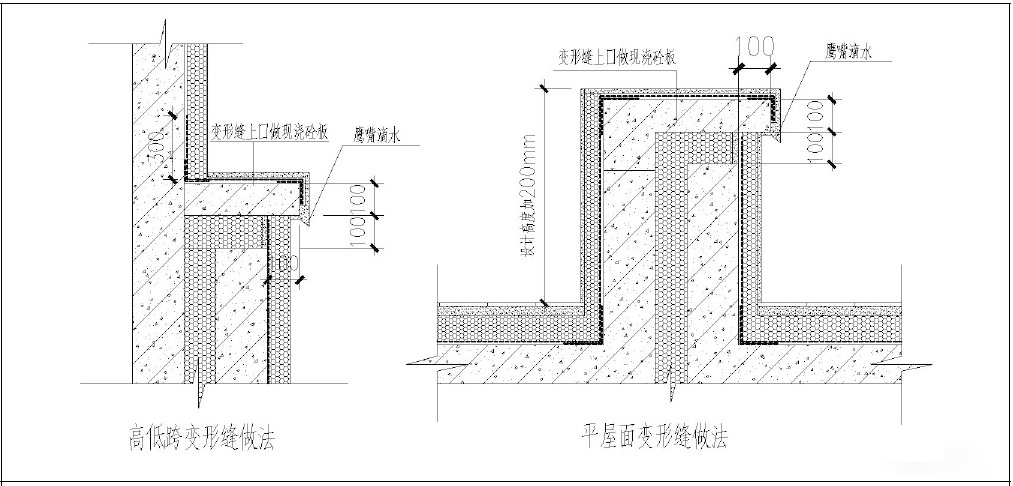

1. Practice of deformation joint of flat roof

① The internal reinforcement of post cast slab refers to air conditioning slab.

② Waterproof is added to the top of the post cast slab, and the method is the same as that of the roof.

2. Practice of roof side rainwater outlet

① The finished rainwater inlet shall be embedded in the structure construction, and shall not be set after construction.

② The bottom surface of the inner side of the rainwater inlet is level with the structural plate.

③ The roof panel adopts structural slope making and one-time calendering.

④ When purchasing, the total thickness of external decorative surface must be considered.

3. Practice of pipe root out of roof

① The pipe out of the roof must be provided with sleeve with wing ring.

② The sleeve is 100 mm higher than the decorative surface of the roof.

③ After the completion of the insulation protection layer, the 300 mm high fine aggregate concrete pier and abutment shall be poured at the pipe root.

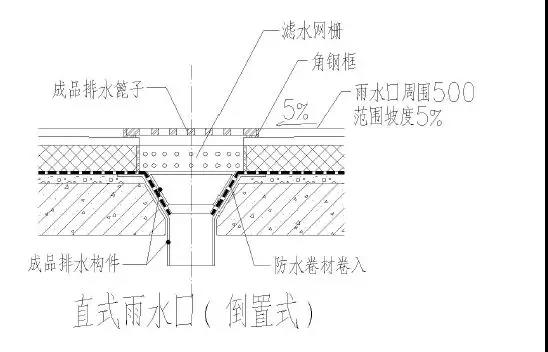

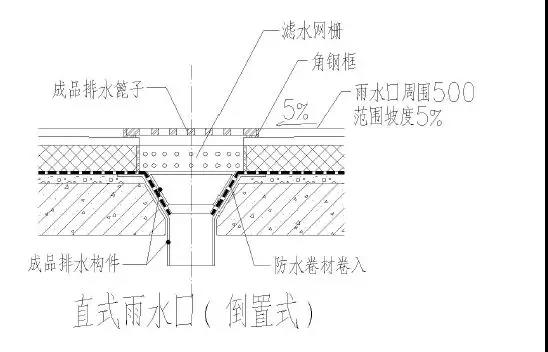

4. Practice of roof direct drainage inlet

① The top surface of the inlet is flat with the structural plane.

② The waterproof coiled material shall not be less than 50mm drawn into the rainwater inlet.

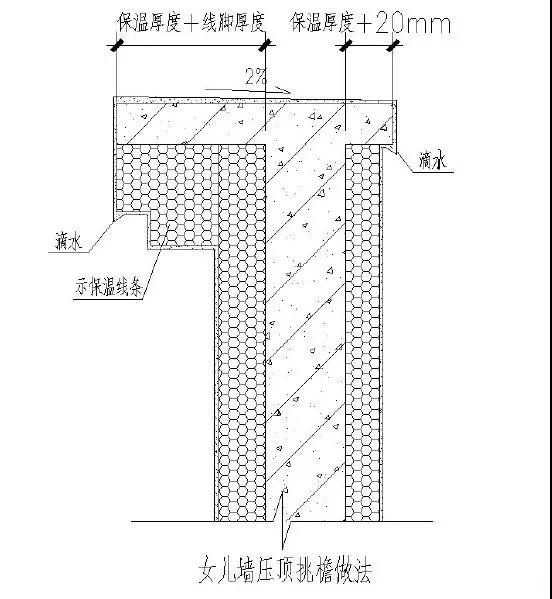

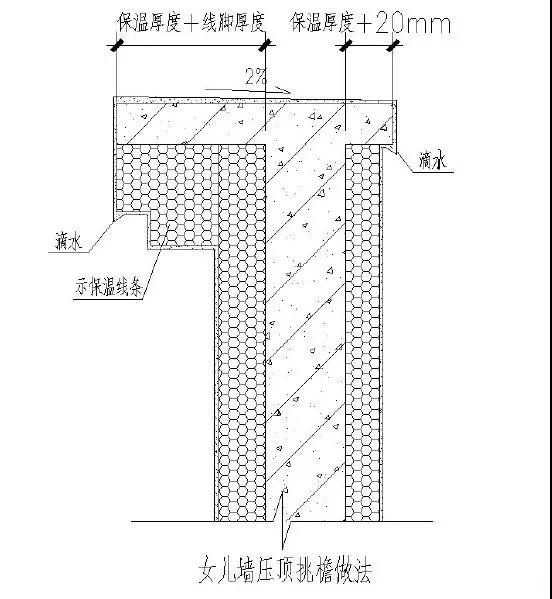

5. Practice of roof parapet coping and overhanging eaves

① Concrete overhanging eaves must be added at the junction of wall top and external insulation.

② The overhanging width of overhanging eaves is the same as the thickness of external thermal insulation (when there are thermal insulation lines, cover the lines).

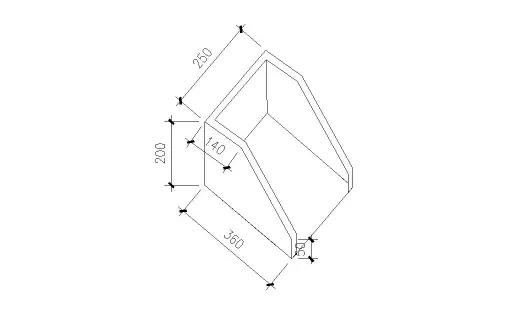

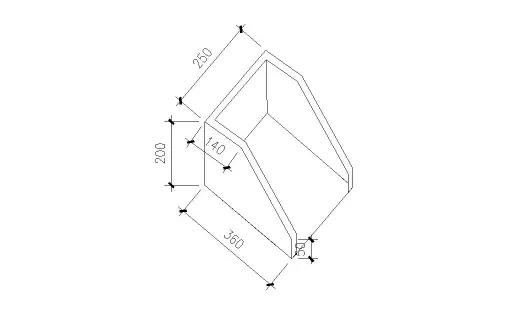

6. Roof water dustpan

① It is made of 15mm thick gray granite

② The bonding is firm and the glue joint is even and straight.

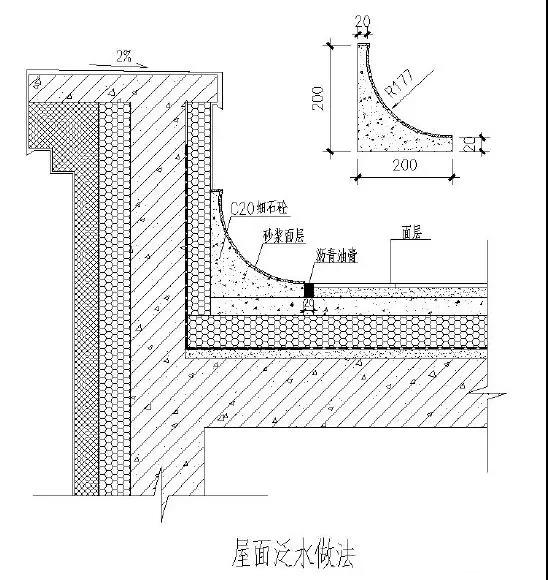

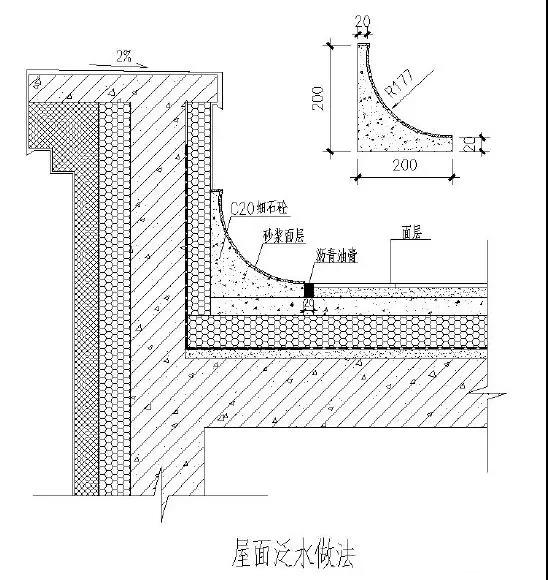

7. Roof flashing

Make arc flashing at the root of parapet and roof components.

8. Retaining of steel bar head on inclined roof

① The diameter of reinforcement head is round 6.

② The two-way spacing of reinforcement head is 900mm.

③ The exposed length of reinforcement head is 200 mm.

③ When the steel bar head is embedded, the two-way stay wire shall be used for alignment.

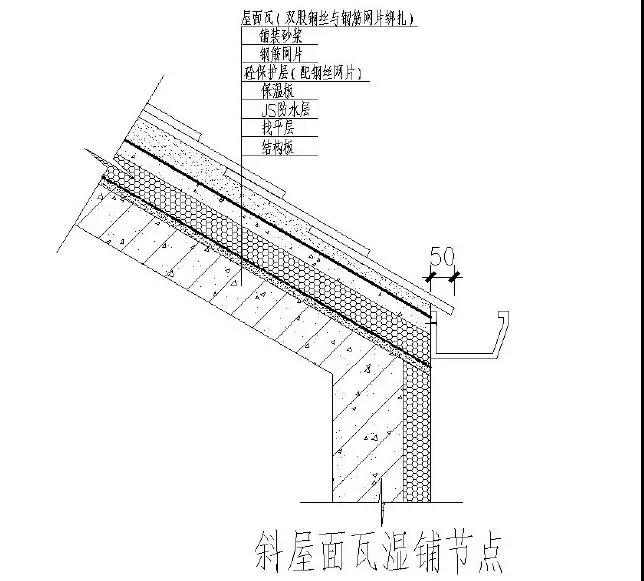

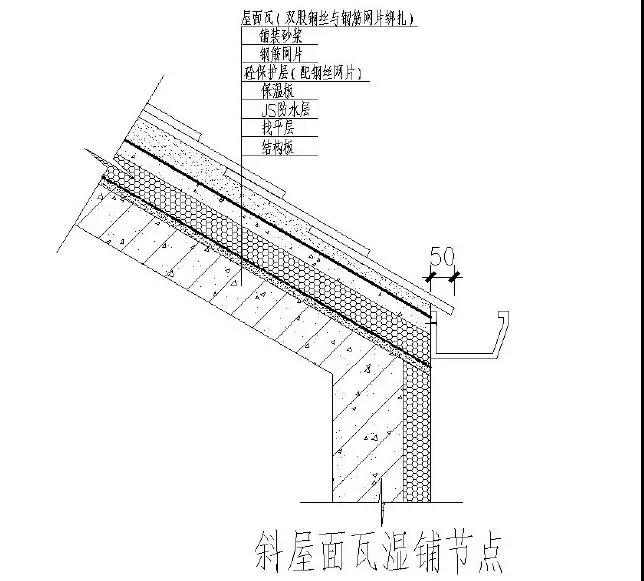

9. Wet paving joint of inclined roof tile

① Setting of steel mesh: a round 6 steel bar shall be set at the ridge, the spacing of steel bars perpendicular to the ridge shall not be greater than 900mm, and the spacing of steel bars parallel to the ridge shall be determined according to the size of roof tile.

② The roof tile is bound firmly with double strands of copper wire and mesh reinforcement.

③ The bonding area of tile laying mortar shall not be less than 90%.

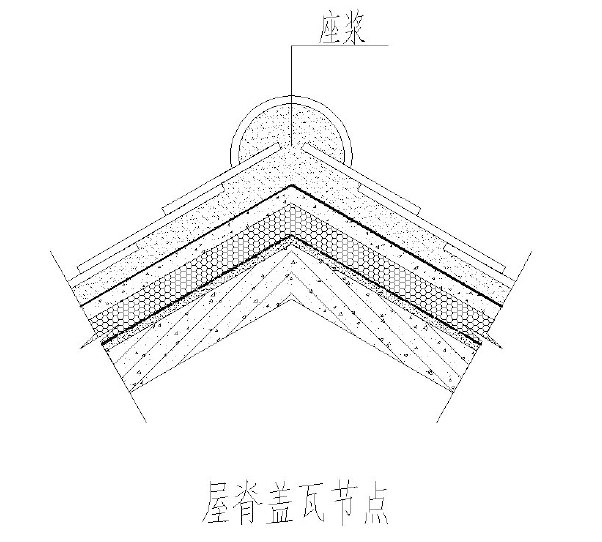

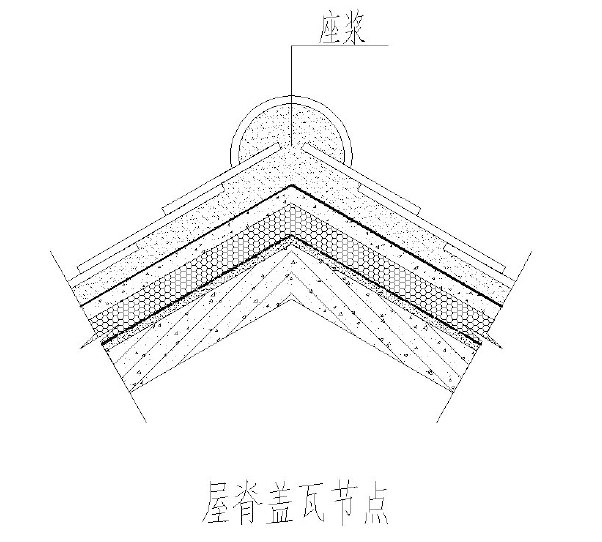

10. Wet laid ridge tile joint

① Hang the whole line and straighten it.

② Double strands of copper wire are pressed into the mortar.

③ The pulp is full.

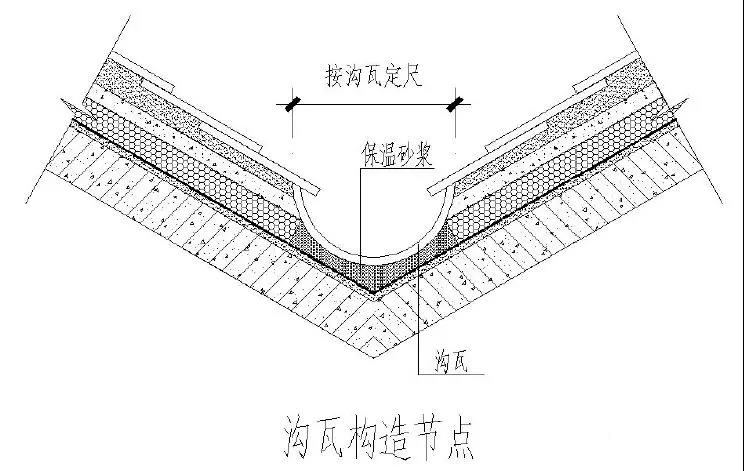

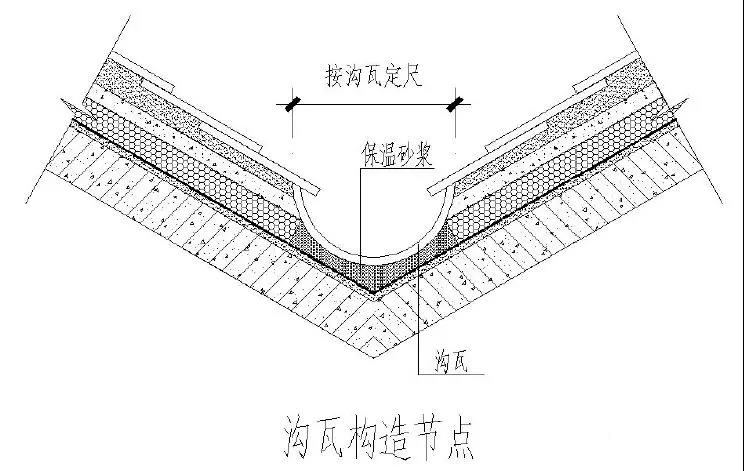

11. Wet laid trench tile joint

If the insulation board cannot be laid at the bottom of the trench, the insulation mortar shall be used.

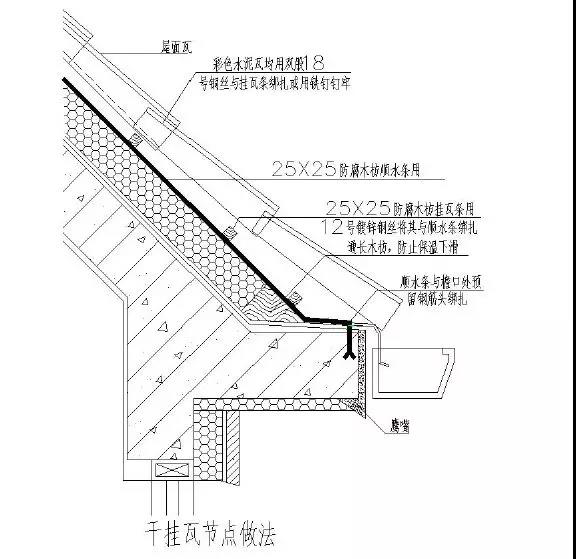

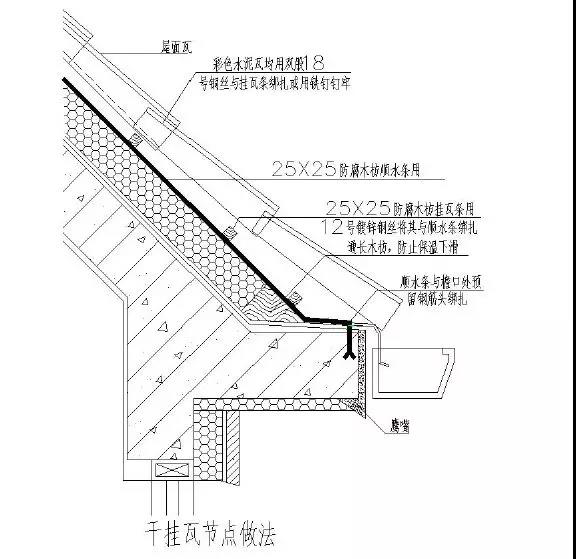

12. Dry hanging cornice tile joint

① The ridge and cornice are embedded with 8 round reinforcement heads, and the middle distance is 700mm.

② The cement tile and the hanging tile strip are bound with double strands of copper wire or fixed with iron nails (see the design drawings for details).

13. Dry hanging tile hanging Hill node

① Waterproof down to cornice 100 mm.

② External angle steel mesh shall be hung at cornice plastering and closing.

14. Dry hanging tile ridge joint

① Hang the whole line and straighten it.

② Fixed with galvanized screws.

③ The finished bracket is firmly bound with the full-length timber.

④ The finished bracket is firmly welded with the embedded steel head.

(Disclaimer: the copyright of this article belongs to the original author and the original source. If the original copyright owner does not agree to reprint, please contact this number in time so that this number can delete the work immediately. Contact hotline: 17705693910)

1. Practice of deformation joint of flat roof

① The internal reinforcement of post cast slab refers to air conditioning slab.

② Waterproof is added to the top of the post cast slab, and the method is the same as that of the roof.

2. Practice of roof side rainwater outlet

① The finished rainwater inlet shall be embedded in the structure construction, and shall not be set after construction.

② The bottom surface of the inner side of the rainwater inlet is level with the structural plate.

③ The roof panel adopts structural slope making and one-time calendering.

④ When purchasing, the total thickness of external decorative surface must be considered.

3. Practice of pipe root out of roof

① The pipe out of the roof must be provided with sleeve with wing ring.

② The sleeve is 100 mm higher than the decorative surface of the roof.

③ After the completion of the insulation protection layer, the 300 mm high fine aggregate concrete pier and abutment shall be poured at the pipe root.

4. Practice of roof direct drainage inlet

① The top surface of the inlet is flat with the structural plane.

② The waterproof coiled material shall not be less than 50mm drawn into the rainwater inlet.

5. Practice of roof parapet coping and overhanging eaves

① Concrete overhanging eaves must be added at the junction of wall top and external insulation.

② The overhanging width of overhanging eaves is the same as the thickness of external thermal insulation (when there are thermal insulation lines, cover the lines).

6. Roof water dustpan

① It is made of 15mm thick gray granite

② The bonding is firm and the glue joint is even and straight.

7. Roof flashing

Make arc flashing at the root of parapet and roof components.

8. Retaining of steel bar head on inclined roof

① The diameter of reinforcement head is round 6.

② The two-way spacing of reinforcement head is 900mm.

③ The exposed length of reinforcement head is 200 mm.

③ When the steel bar head is embedded, the two-way stay wire shall be used for alignment.

9. Wet paving joint of inclined roof tile

① Setting of steel mesh: a round 6 steel bar shall be set at the ridge, the spacing of steel bars perpendicular to the ridge shall not be greater than 900mm, and the spacing of steel bars parallel to the ridge shall be determined according to the size of roof tile.

② The roof tile is bound firmly with double strands of copper wire and mesh reinforcement.

③ The bonding area of tile laying mortar shall not be less than 90%.

10. Wet laid ridge tile joint

① Hang the whole line and straighten it.

② Double strands of copper wire are pressed into the mortar.

③ The pulp is full.

11. Wet laid trench tile joint

If the insulation board cannot be laid at the bottom of the trench, the insulation mortar shall be used.

12. Dry hanging cornice tile joint

① The ridge and cornice are embedded with 8 round reinforcement heads, and the middle distance is 700mm.

② The cement tile and the hanging tile strip are bound with double strands of copper wire or fixed with iron nails (see the design drawings for details).

13. Dry hanging tile hanging Hill node

① Waterproof down to cornice 100 mm.

② External angle steel mesh shall be hung at cornice plastering and closing.

14. Dry hanging tile ridge joint

① Hang the whole line and straighten it.

② Fixed with galvanized screws.

③ The finished bracket is firmly bound with the full-length timber.

④ The finished bracket is firmly welded with the embedded steel head.

(Disclaimer: the copyright of this article belongs to the original author and the original source. If the original copyright owner does not agree to reprint, please contact this number in time so that this number can delete the work immediately. Contact hotline: 17705693910)