Detailed explanation of waterproof technology for pre-laying building cushion

publishdate:2021-07-06 views:70

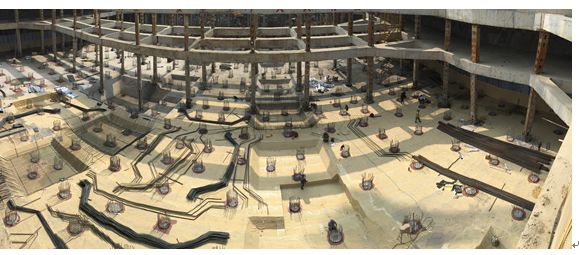

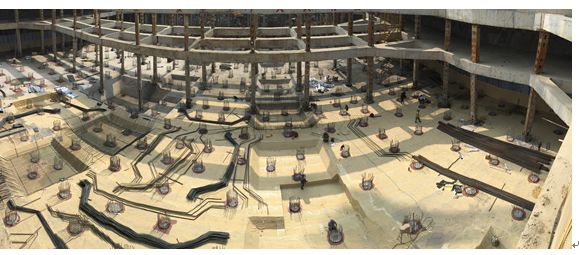

Underground engineering generally adopts the construction method of large excavation. In the past, underground waterproofing adopted the "outer protection and pasting" method, that is, a cushion layer is applied after the foundation pit is dug, a waterproof layer is constructed on the cushion layer, and the bottom plate is poured. Then pour the side walls, and after the corners are connected, the entire side wall surface is made a waterproof layer.

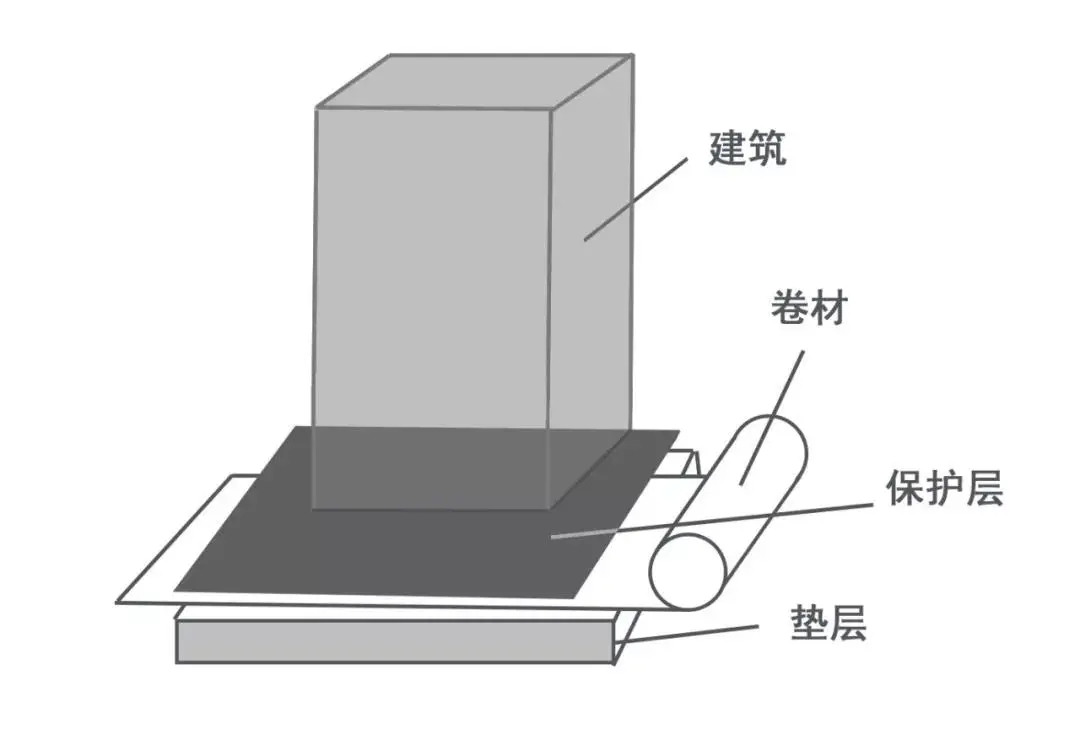

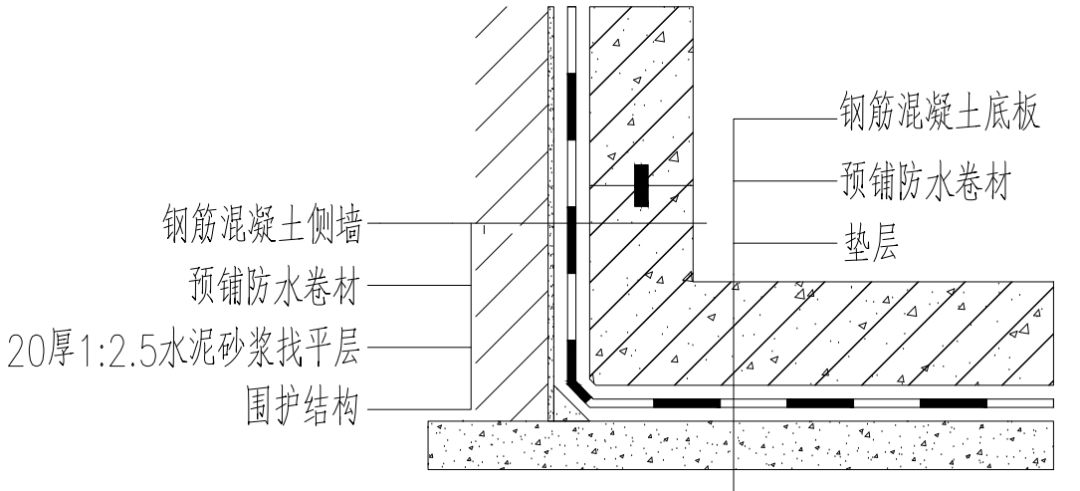

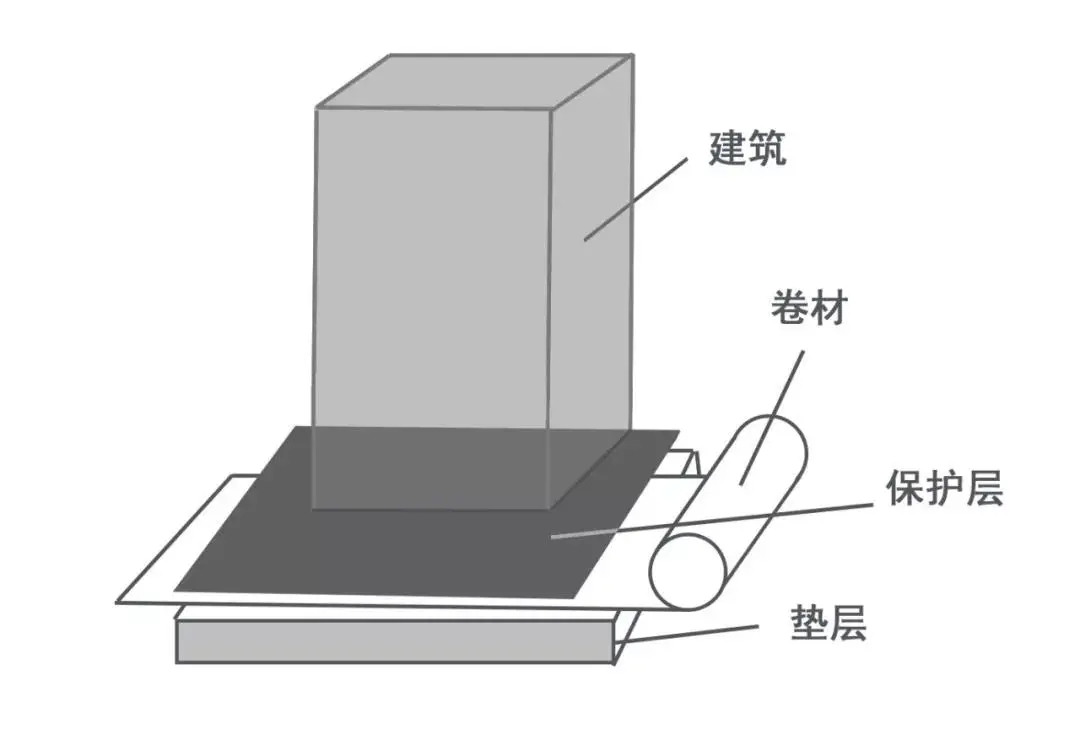

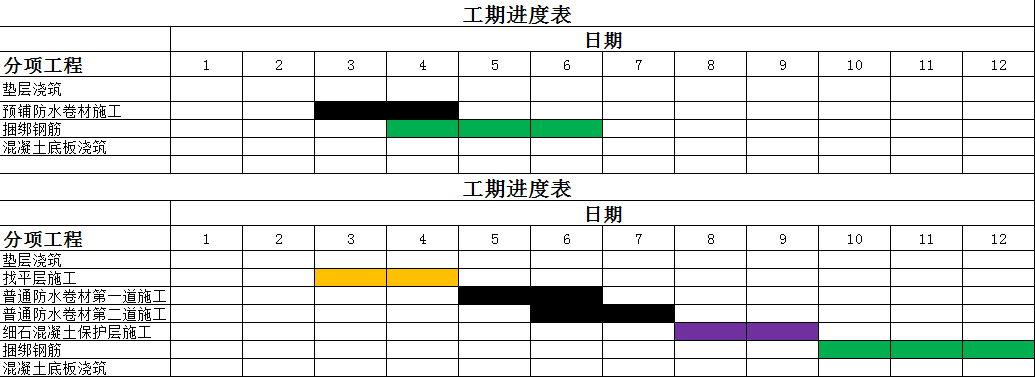

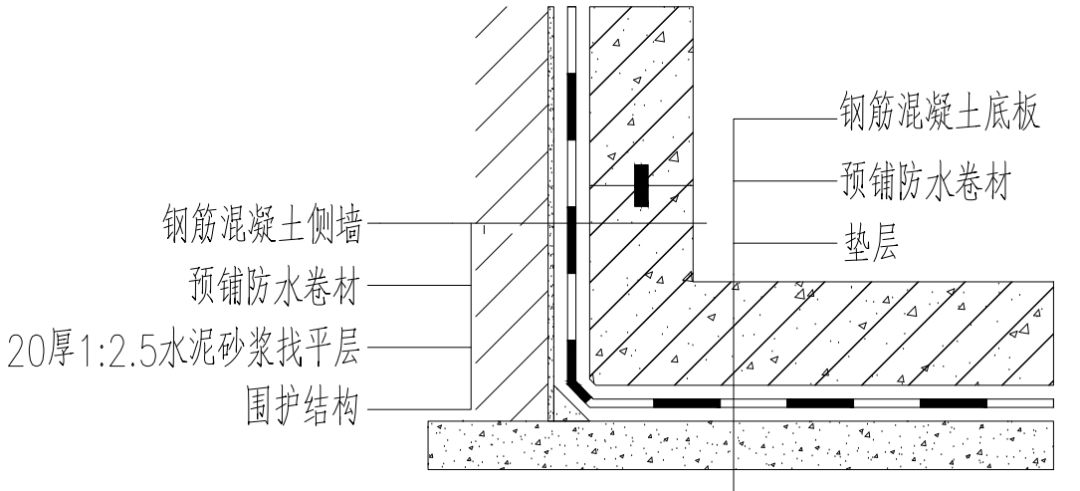

The "pre-laying process" is based on rubber and plastic as the base material, single-sided composite, polymer self-adhesive, and the surface of the waterproof membrane is treated with non-stick or tack-reducing materials, with the self-adhesive layer facing upwards, and empty on the cement On the cushion layer, the seams are bonded by the self-adhesive layer, then the steel bars are tied and concrete is poured. The concrete is completely bonded with the molecular self-adhesive layer during the solidification process to prevent water from flowing in the bonding interface under the action of water, thereby minimizing the risk of leakage.

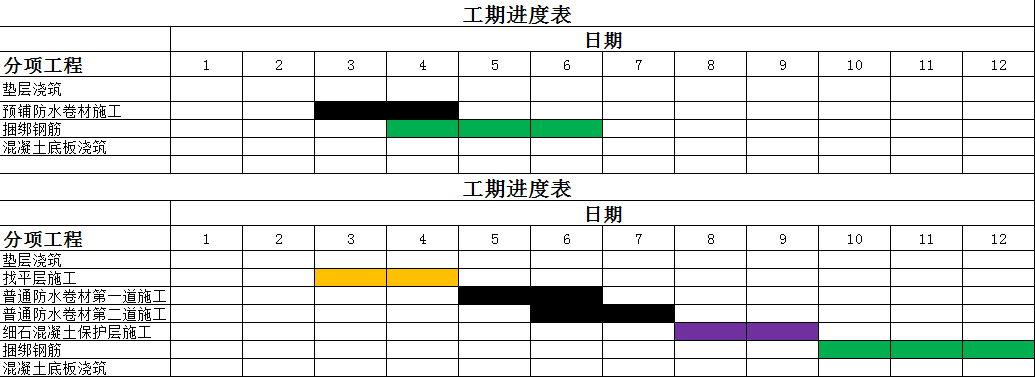

The advantages of the "pre-laying process": 1. Adopting the empty paving and self-adhesive bonding of the seams, the construction efficiency is fast, which is 6-8 times that of the traditional; 2. The flatness, smoothness, and moisture of the cement cushion, etc., Low requirements, as long as there is no clear water can be constructed. After the completion of the construction, after the waterproof layer is qualified, you can tie the steel bars and pour the concrete; 3. The construction environment is low, and the construction can be carried out above -10°C in winter, even in light rain, as long as the joints are handled well, the construction can be carried out. 4. The pre-laid waterproof coiled material has good puncture resistance, and the general steel tying will not puncture the waterproof coiled material. If it is damaged, just use the double-sided self-adhesive coiled material to repair it in time; 5. The pre-paved waterproof coiled material is completely bonded to the post-poured concrete, and the water resistance is good. Even if there is a small damage, the water will not flow everywhere. There will be no leakage problems;

6. The pre-paved waterproofing membrane has strong resistance to sediment pollution, that is, there is silt pollution, and will not reduce its cohesiveness and anti-channeling water; 7. The pre-paved waterproofing membrane is especially suitable for small excavated underground spaces, bottom plates and The side wall is constructed in a continuous and integrated manner, avoiding the problems of "external protection and external sticking method" construction in the past, and the construction difficulties caused by the narrow construction space of the side wall; 8. The bottom plate is used in a single layer, without a cement protective layer, and the overall cost Low; 9. The pre-laid waterproof coiled material adopts the cold construction process of empty paving and self-adhesive joints, which avoids the danger of hot construction, and pollution, and is green and environmentally friendly;

Underground engineering generally adopts the construction method of large excavation. In the past, underground waterproofing adopted the "outer protection and pasting" method, that is, a cushion layer is applied after the foundation pit is dug, a waterproof layer is constructed on the cushion layer, and the bottom plate is poured. Then pour the side walls, and after the corners are connected, the entire side wall surface is made a waterproof layer.

The "pre-laying process" is based on rubber and plastic as the base material, single-sided composite, polymer self-adhesive, and the surface of the waterproof membrane is treated with non-stick or tack-reducing materials, with the self-adhesive layer facing upwards, and empty on the cement On the cushion layer, the seams are bonded by the self-adhesive layer, then the steel bars are tied and concrete is poured. The concrete is completely bonded with the molecular self-adhesive layer during the solidification process to prevent water from flowing in the bonding interface under the action of water, thereby minimizing the risk of leakage.

The advantages of the "pre-laying process": 1. Adopting the empty paving and self-adhesive bonding of the seams, the construction efficiency is fast, which is 6-8 times that of the traditional; 2. The flatness, smoothness, and moisture of the cement cushion, etc., Low requirements, as long as there is no clear water can be constructed. After the completion of the construction, after the waterproof layer is qualified, you can tie the steel bars and pour the concrete; 3. The construction environment is low, and the construction can be carried out above -10°C in winter, even in light rain, as long as the joints are handled well, the construction can be carried out. 4. The pre-laid waterproof coiled material has good puncture resistance, and the general steel tying will not puncture the waterproof coiled material. If it is damaged, just use the double-sided self-adhesive coiled material to repair it in time; 5. The pre-paved waterproof coiled material is completely bonded to the post-poured concrete, and the water resistance is good. Even if there is a small damage, the water will not flow everywhere. There will be no leakage problems;

6. The pre-paved waterproofing membrane has strong resistance to sediment pollution, that is, there is silt pollution, and will not reduce its cohesiveness and anti-channeling water; 7. The pre-paved waterproofing membrane is especially suitable for small excavated underground spaces, bottom plates and The side wall is constructed in a continuous and integrated manner, avoiding the problems of "external protection and external sticking method" construction in the past, and the construction difficulties caused by the narrow construction space of the side wall; 8. The bottom plate is used in a single layer, without a cement protective layer, and the overall cost Low; 9. The pre-laid waterproof coiled material adopts the cold construction process of empty paving and self-adhesive joints, which avoids the danger of hot construction, and pollution, and is green and environmentally friendly;