【Basic Regulations】

1.1 In the design of building waterproof engineering, the fortification standard and waterproof fortification level should be determined according to the nature and importance of the building, functional requirements, structural characteristics, construction conditions, and environmental conditions; according to the characteristics of materials and the compatibility between levels Reasonably select the types and specifications of waterproof materials, determine the structure and detailed structure methods, and propose corresponding technical measures.

1.2 The waterproof design should follow the design principles of "prevention first", "fortification against the water surface", "rigid and flexible", and "combination of prevention and drainage", and deepen the design according to the complexity of the project to ensure the correct implementation of the waterproof design and waterproofing The realization of the function.

1.3 The waterproof material used in the waterproofing project should have a product qualification certificate and performance test report, and the variety, specification, performance, etc. of the material should meet the national product standards and design requirements.

1.4 Waterproof engineering design should meet the requirements of waterproof fortification, the detailed structure treatment should be clear and reasonable, and should be coordinated with the structure, water supply and drainage, building electrical, air conditioning and ventilation, decoration, garden environment and other professions according to the actual situation of the site.

1.5 A protective layer should be set on the flexible waterproof layer, and the choice of protective layer material should be considered compatible with the waterproof layer material and does not interfere with the use of the building.

【Waterproof roof】

2.1 The roof waterproof should meet the following general requirements:

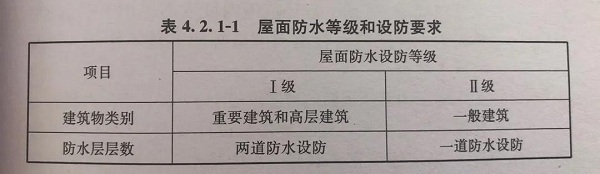

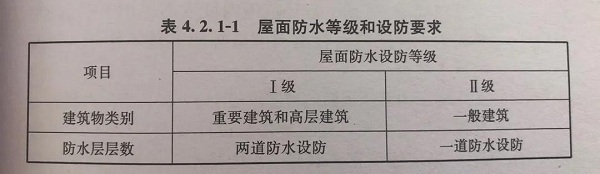

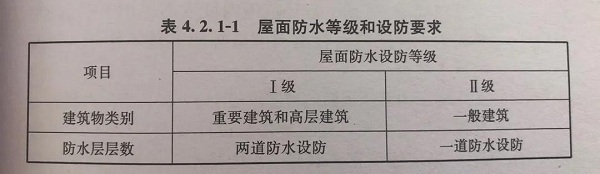

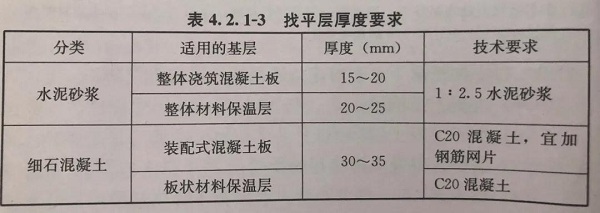

1. The roof waterproofing project should be divided into waterproof grades according to the building type, importance, and functional requirements, and waterproof fortification should be carried out according to the corresponding grade; building roofs with special requirements for waterproofing should be specially designed for waterproofing. For roof waterproofing, the number of waterproof layers, the types of materials used and the waterproof measures shall be determined according to the reasonable service life of the waterproof layer, and shall meet the requirements of Table 4.2.1-1.

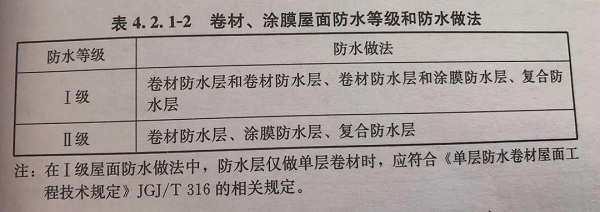

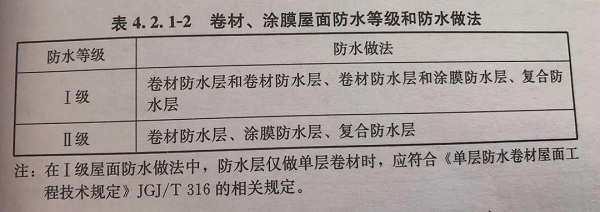

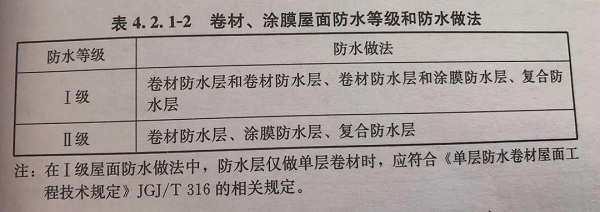

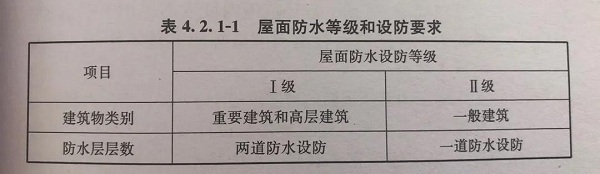

2. The waterproof grade and water-proof method of coiled material and coating film shall meet the requirements of Table 4.2.1-2.

3. Under the following circumstances, it shall not be used as a waterproof fortification of the roof:

1) Concrete structure layer;

2) Fine stone concrete layer;

3) Decorative tiles and roofs without overlapping tiles;

4) Vapor barrier;

5) The thickness of the coiled material or the coating film does not meet the waterproof layer specified in this regulation;

6) Type I spraying rigid foam polyurethane insulation layer.

4. The roof slope design should meet the following requirements:

1) Flat roof drainage slope: When the building function allows, the structure should be used to find the slope, and the structure should not be less than 3%; when the material is used to find the slope, the slope should not be less than 2%, and the watershed should be determined in the construction drawings And drainage slope;

2) The longitudinal slope of the reinforced concrete gutter and Yugou shall not be less than 1%; the longitudinal slope of the metal gutter and eaves shall not be less than 0.5%;

3) The slope within the 50m diameter range around the water drop opening should not be less than 5%, and water accumulation is strictly prohibited; a drainage slope with a height of not less than 30mm should be wiped out around the pipe extending out of the roof;

4) The lateral slope of parapet and gable top should not be less than 5%, and should be inclined inward.

5. The number of downpipes should be carried out in accordance with the relevant regulations of "Code for Design of Building Water Supply and Drainage" GB 50015. High-rise buildings should adopt organized internal drainage. Drainage from gutters and eaves shall not flow through deformation joints.

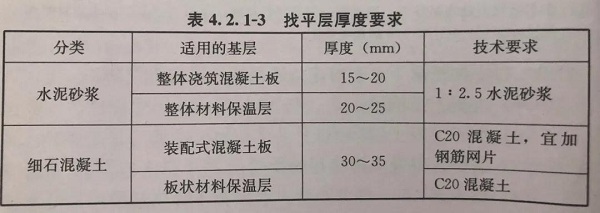

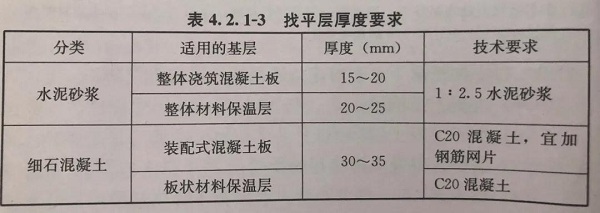

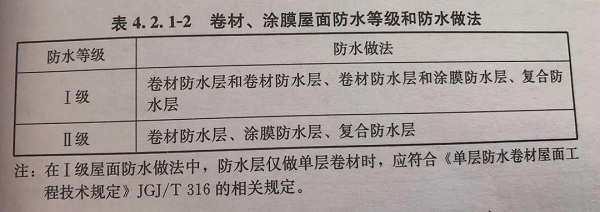

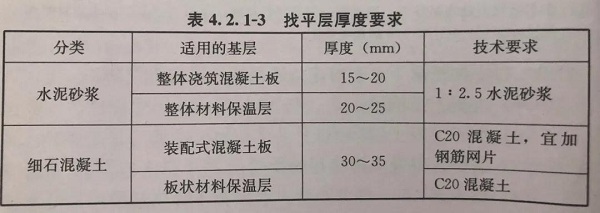

6. When fabricated reinforced concrete slabs are used for the roof structure, fine-stone concrete with a strength grade of not less than C20 should be poured into the slab joints. When the width of the slab seam is greater than 40mm or the diagonal seam, structural steel bars should be installed in the slab seam, and the end seam of the slab should be sealed. 7 The leveling layer should be made of cement mortar and fine stone concrete, and its thickness should meet the requirements of Table 4.2.1-3.

7. The leveling layer should be made of cement mortar and fine stone concrete, and its thickness should meet the requirements of Table 4.2 1-3.

8. The leveling layer on the thermal insulation layer should be left with split joints, the vertical and horizontal spacing should not be greater than 6m, the width of the joint should be 5-20mm, and the sealing material should be embedded.

9. Roof waterproof The detailed structure should be multi-channel fortification, composite materials, continuous sealing, local reinforcement, and should meet the requirements of use function, temperature difference and deformation, construction environmental conditions and operability.

10. The upper part of the high parapet wall should be waterproofed.

11. Inverted roof waterproofing practices should comply with the "Inverted Roof Engineering Technical Regulations" JGJ 230.

2.2 The design of coiled waterproof roof should meet the following requirements:

1. For roofs with large-span grid structures, large roof panel structures, light structures with large base elastic deformations, fabricated roofs, roofs subject to vibration or impact, synthetic polymer waterproofing membranes should be used for the waterproof layer, and should be used Paving techniques such as empty laying method, point sticking method, strip sticking method or mechanical fixing method should be fully glued within 800mm from the periphery of the roof, and the coil and the coil should also be fully glued. And an additional layer of empty paving should be set at the joint of the slab end seam, roof slab and gutter, and the width of the empty paving should be 200~300mm.

2. When the waterproof coiled material is used in combination with the waterproof coating, the waterproof coating should be on the bottom, and the coiled material should be on the top, and the material properties should be compatible: volatile-curing waterproof coatings should not be used as the refined material of the waterproof coiled material. The seam should be sealed with a material compatible sealing material or welded and sealed with its own material.

【Basic Regulations】

1.1 In the design of building waterproof engineering, the fortification standard and waterproof fortification level should be determined according to the nature and importance of the building, functional requirements, structural characteristics, construction conditions, and environmental conditions; according to the characteristics of materials and the compatibility between levels Reasonably select the types and specifications of waterproof materials, determine the structure and detailed structure methods, and propose corresponding technical measures.

1.2 The waterproof design should follow the design principles of "prevention first", "fortification against the water surface", "rigid and flexible", and "combination of prevention and drainage", and deepen the design according to the complexity of the project to ensure the correct implementation of the waterproof design and waterproofing The realization of the function.

1.3 The waterproof material used in the waterproofing project should have a product qualification certificate and performance test report, and the variety, specification, performance, etc. of the material should meet the national product standards and design requirements.

1.4 Waterproof engineering design should meet the requirements of waterproof fortification, the detailed structure treatment should be clear and reasonable, and should be coordinated with the structure, water supply and drainage, building electrical, air conditioning and ventilation, decoration, garden environment and other professions according to the actual situation of the site.

1.5 A protective layer should be set on the flexible waterproof layer, and the choice of protective layer material should be considered compatible with the waterproof layer material and does not interfere with the use of the building.

【Waterproof roof】

2.1 The roof waterproof should meet the following general requirements:

1. The roof waterproofing project should be divided into waterproof grades according to the building type, importance, and functional requirements, and waterproof fortification should be carried out according to the corresponding grade; building roofs with special requirements for waterproofing should be specially designed for waterproofing. For roof waterproofing, the number of waterproof layers, the types of materials used and the waterproof measures shall be determined according to the reasonable service life of the waterproof layer, and shall meet the requirements of Table 4.2.1-1.

2. The waterproof grade and water-proof method of coiled material and coating film shall meet the requirements of Table 4.2.1-2.

3. Under the following circumstances, it shall not be used as a waterproof fortification of the roof:

1) Concrete structure layer;

2) Fine stone concrete layer;

3) Decorative tiles and roofs without overlapping tiles;

4) Vapor barrier;

5) The thickness of the coiled material or the coating film does not meet the waterproof layer specified in this regulation;

6) Type I spraying rigid foam polyurethane insulation layer.

4. The roof slope design should meet the following requirements:

1) Flat roof drainage slope: When the building function allows, the structure should be used to find the slope, and the structure should not be less than 3%; when the material is used to find the slope, the slope should not be less than 2%, and the watershed should be determined in the construction drawings And drainage slope;

2) The longitudinal slope of the reinforced concrete gutter and Yugou shall not be less than 1%; the longitudinal slope of the metal gutter and eaves shall not be less than 0.5%;

3) The slope within the 50m diameter range around the water drop opening should not be less than 5%, and water accumulation is strictly prohibited; a drainage slope with a height of not less than 30mm should be wiped out around the pipe extending out of the roof;

4) The lateral slope of parapet and gable top should not be less than 5%, and should be inclined inward.

5. The number of downpipes should be carried out in accordance with the relevant regulations of "Code for Design of Building Water Supply and Drainage" GB 50015. High-rise buildings should adopt organized internal drainage. Drainage from gutters and eaves shall not flow through deformation joints.

6. When fabricated reinforced concrete slabs are used for the roof structure, fine-stone concrete with a strength grade of not less than C20 should be poured into the slab joints. When the width of the slab seam is greater than 40mm or the diagonal seam, structural steel bars should be installed in the slab seam, and the end seam of the slab should be sealed. 7 The leveling layer should be made of cement mortar and fine stone concrete, and its thickness should meet the requirements of Table 4.2.1-3.

7. The leveling layer should be made of cement mortar and fine stone concrete, and its thickness should meet the requirements of Table 4.2 1-3.

8. The leveling layer on the thermal insulation layer should be left with split joints, the vertical and horizontal spacing should not be greater than 6m, the width of the joint should be 5-20mm, and the sealing material should be embedded.

9. Roof waterproof The detailed structure should be multi-channel fortification, composite materials, continuous sealing, local reinforcement, and should meet the requirements of use function, temperature difference and deformation, construction environmental conditions and operability.

10. The upper part of the high parapet wall should be waterproofed.

11. Inverted roof waterproofing practices should comply with the "Inverted Roof Engineering Technical Regulations" JGJ 230.

2.2 The design of coiled waterproof roof should meet the following requirements:

1. For roofs with large-span grid structures, large roof panel structures, light structures with large base elastic deformations, fabricated roofs, roofs subject to vibration or impact, synthetic polymer waterproofing membranes should be used for the waterproof layer, and should be used Paving techniques such as empty laying method, point sticking method, strip sticking method or mechanical fixing method should be fully glued within 800mm from the periphery of the roof, and the coil and the coil should also be fully glued. And an additional layer of empty paving should be set at the joint of the slab end seam, roof slab and gutter, and the width of the empty paving should be 200~300mm.

2. When the waterproof coiled material is used in combination with the waterproof coating, the waterproof coating should be on the bottom, and the coiled material should be on the top, and the material properties should be compatible: volatile-curing waterproof coatings should not be used as the refined material of the waterproof coiled material. The seam should be sealed with a material compatible sealing material or welded and sealed with its own material.